We deal with a wide variety of indoor air quality concerns, and often get called in when other contractors have been stumped. Recently, one of our clients had been dealing with a significant buildup of dust and health concerns after a new furnace had been installed. We identified pressure imbalances, and borate dust from the cellulose insulation in the attic. Keep reading to hear about the testing and inspection that was done to get to this conclusion, and call or email us if you have indoor air quality concerns in your building

Background information:

The client is the first owner of the home and has lived there since it’s original construction in 2004.

Home owner’s statements:

- Prior to the replacement of the HVAC system the home had normal levels of dust and no health concerns were noted.

- In February of 2012 the home’s original furnace failed and a new unit was installed.

- When the new furnace was installed the home owner began to experience health effects when in the home.

- The initial health concerns were suspected to be related to ozone gas production in the electronic filter and the HVAC company replaced this unit with a standard 4” pleated media filter.

- On 1/31/2012 the HVAC company performed extensive duct sealing and replaced the return ducting where is passes through the attic.

The home owner complains of:

- Excessive dust in the home

- Dry skin

- Eye irritation

- Persistent coughing

- Feelings of breathing in sand and sand in eyes

- Dying houseplants

Suspected issues:

Based on the reported concerns and the obvious dust in the home, a pressure imbalance that has led to infiltration of the fire-retardant additives in the cellulose insulation (borates).

LIVING SPACE VENTILATION

The living space in the home is currently ventilated by:

- The kitchen range exhaust hood appears to be ducted to the exterior.

- One exhaust fan/light unit was observed in the master bathroom main area and tested at 51 CFM (using Alnor 6200 Balometer)

- One exhaust fan/light unit was observed in the master bathroom water closet and tested at 57 CFM (using Alnor 6200 Balometer)

- One exhaust fan unit was observed in the laundry room and tested at 12 CFM (using Alnor 6200 Balometer). This fan is controlled by a 24-hour mechanical timer located in the master bathroom closet.

- One exhaust fan/light unit was observed in the hall bathroom and tested at 68 CFM (using Alnor 6200 Balometer)

- The furnace is equipped with a fresh-air intake duct that was tested at 50 CFM (using Alnor 6200 Balometer) and is controlled by a manual damper that was screwed into its current position and could not be adjusted.

Environmental Data (home in normal operating condition):

| Location | Temperature | Relative Humidity | Carbon Dioxide (CO2) | TVOC level | Carbon Monoxide (CO) |

|---|---|---|---|---|---|

Outdoor | 38.5 °F | 82.5 % | 406 ppm | 79 ppb | 0 ppm |

Master Bedroom | 71.7 °F | 34.5 % | 663 ppm | 183 ppb | 0 ppm |

Master Bathroom | 72.1 °F | 35.1 % | 645 ppm | 180 ppb | 0 ppm |

Living Room | 72.2 °F | 30.8 % | 688 ppm | 181 ppb | 0 ppm |

Kitchen | 72.6 °F | 31.2 % | 696 ppm | 170 ppb | 0 ppm |

Dining Room | 72.6 °F | 30.7 % | 683 ppm | 170 ppb | 0 ppm |

Bedroom 1 | 72.3 °F | 28.8 % | 657 ppm | 167 ppb | 0 ppm |

Hall Bathroom | 72.1 °F | 30.5 % | 649 ppm | 176 ppb | 0 ppm |

Bedroom 2 (w/attic hatch) | 72.6 °F | 29.5 | 658 ppm | 160 ppb | 0 ppm |

Office | 72.3 °F | 30.9 | 677 ppm | 176 ppb | 0 ppm |

Recommended Ventilation Rates:

As per 2013 ASHRAE 62.2 (these requirements are in excess of Washington State’s most current building codes, but Hawk Environmental Services prefers a more liberal ventilation plan)

Floor Area in Ft2 | Number of Bedrooms | ||||

|---|---|---|---|---|---|

1 | 2 | 3 | 4 | 5 | |

<500 | 30 | 38 | 45 | 53 | 60 |

501-1000 | 45 | 53 | 60 | 68 | 75 |

1001-1500 | 60 | 68 | 75 | 83 | 90 |

1501-2000 | 75 | 83 | 90 | 98 | 105 |

2501-3000 | 105 | 113 | 120 | 128 | 13 |

3001-3500 | 120 | 128 | 135 | 143 | 150 |

3501-4000 | 135 | 143 | 150 | 158 | 165 |

4001-4500 | 150 | 158 | 165 | 173 | 180 |

4501-5000 | 165 | 173 | 180 | 188 | 195 |

Recommended ventilation improvements:

The CO2, RH, and tVOC levels in the home were within normal limits. If any changes to the fresh-air intake system are made the client should adjust fan settings to achieve the desired rates listed above. Once a final plan for ventilation is established, the client may contact Hawk Environmental Services for assistance with fan setting recommendations. Pressure Testing:

Energy Conservatory DG-700 Manometer Data

| Testing condition | Pressure difference | Tested Location | Reference Location |

| No fans or HVAC running | -1.4 pa | Inside | Outside |

| HVAC only running | -0.7 pa | Inside | Outside |

| Bath and laundry fans only | -4.1 pa | Inside | Outside |

| Kitchen, bath, and laundry fans | -7.8 pa | Inside | Outside |

| Kitchen and bath fans on and dryer running | -9.8 pa | Inside | Outside |

| No fans or HVAC running | 0.9 pa | Inside | Attic (Master Bedroom hatch) |

| HVAC only running | 1.3 pa | Inside | Attic (Master Bedroom hatch) |

| Bath and laundry fans only | -2.0 pa | Inside | Attic (Master Bedroom hatch) |

| Kitchen, bath, and laundry fans | -5.4 pa | Inside | Attic (Master Bedroom hatch) |

| Kitchen and bath fans on and dryer running | -7.3 pa | Inside | Attic (Master Bedroom hatch) |

| HVAC. kitchen, bath fans on and dryer running | -6.7 pa | Inside | Attic (Master Bedroom hatch) |

| No fans or HVAC running | -0.4 pa | Inside | Attic (Bedroom 2 hatch) |

| HVAC only running | -1.2 pa | Inside | Attic (Bedroom 2 hatch) |

| HVAC, bath fans and laundry fans | -1.3 pa | Inside | Attic (Bedroom 2 hatch) |

| HVAC, kitchen, bath, and laundry fans | -4.4 pa | Inside | Attic (Bedroom 2 hatch) |

| HVAC, kitchen, bath, laundry fans, and dryer | -6.1 pa | Inside | Attic (Bedroom 2 hatch) |

| No fans or HVAC running | -1.9 pa | Inside | Crawlspace |

| HVAC only running | -0.8 pa | Inside | Crawlspace |

| Bath and laundry fans only | -4.0 pa | Inside | Crawlspace |

| Kitchen, bath, and laundry fans | -7.2 pa | Inside | Crawlspace |

| Kitchen and bath fans on and dryer running | -9.4 pa | Inside | Crawlspace |

*Yellow highlighted lines indicate times when air from the attic is being drawn into the home (at considerable levels).

Evaluation:

- The pressures in the home are considerably imbalanced and air from the attic is being drawn into the home under a variety of circumstances.

- The HVAC system is not currently contributing to the infiltration of attic air into the living space (as seen in the data listed above)

- The reasons for the depressurization when exhaust appliances are in operation are unknown (but, are likely related to energy-efficient construction techniques), but the duct-sealing in 2013 may have exacerbated a depressurization that was already occurring. Without baseline pressure data from before the installation of the HVAC system, no single cause of depressurization can be ascertained.

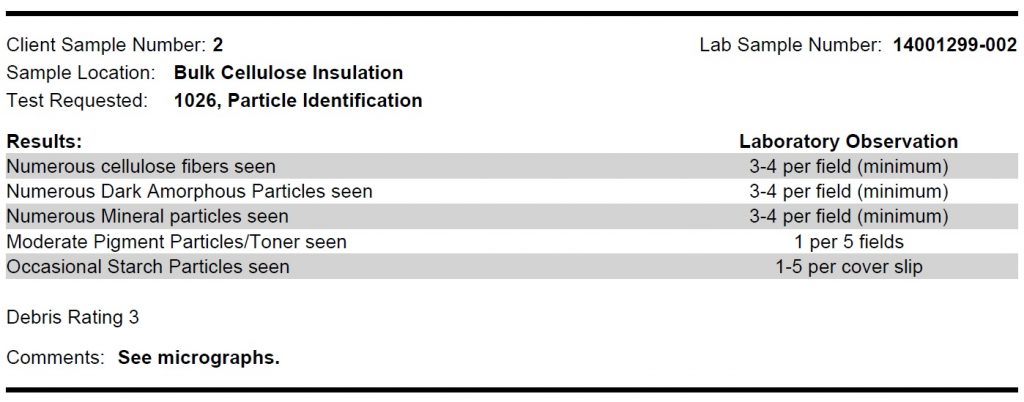

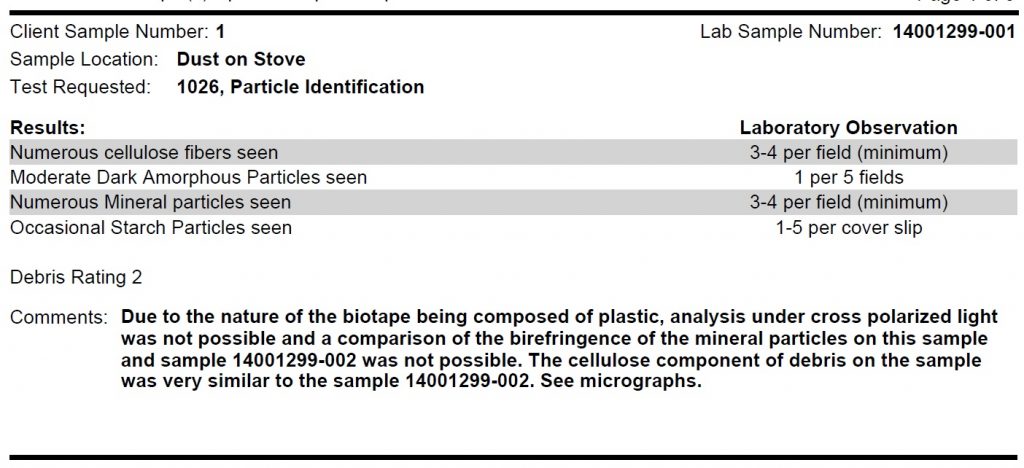

Lab Testing:

Lab Sample Evaluation:

Particle characterizations between both the dust sample from the kitchen stove and the samples of the attic insulation were similar and the micrographs show visually similar crystalline structures that are likely particles of borax fire-retardants that originated in the attic insulation and was drawn into the home during periods of depressurization. The evaluation listed above was based on the on-site inspection, pressure-testing, client history, and visual examination. Additional chemical testing can be performed on the insulation and dust in the home for final confirmation that the noted crystalline structures represent borax, as has been assumed.

NIOSH health and safety information on Borax (the crystalline compound likely present in the cellulose insulation and dust found in the home)

Borax, B4 O7 Na2 . 10H2 O, is also referred to as sodium borate decahydrate, disodium tetraborate decahydrate, sodium tetraborate decahydrate, or sodium pyroborate decahydrate. This compound is a white, odorless, crystalline solid. Sodium tetraborates (includes anhydrous, pentahydrate, and decahydrate) are used in the manufacture of glazes and enamels, are found in cleaning compounds and fertilizers, and are used in the artificial aging of wood.30 Exposure to borates can result in the irritation of the eyes, nose, and throat. High concentrations can lead to gastrointestinal irritation, kidney injury and death.31 An investigation was conducted into the relationship of estimated borax dust exposures to respiratory symptoms, pulmonary function, and chest radiograph abnormalities in actively employed borax workers.32 Acute respiratory irritation symptoms (i. e., dryness of the mouth, nose, and throat; dry cough; nose bleeds; sore throat; productive cough; shortness of breath; and chest tightness) were related to exposures of 4 mg/m3 or more. The study indicated that radiographic abnormalities were uncommon and unrelated to dust exposure, and that borax dust acted as a simple respiratory irritant. NIOSH conducted a health hazard evaluation (HHE) where borax dust samples were collected.33 Eight-hour TWA concentrations ranged from 2.9 mg/m3 to 29.9 mg/m 3 . Employees in the borax area reported symptoms of mucous membrane, eye, nose, and throat irritation; some bleeding after nose-blowing; and dry and chapped hands. Workers industrially exposed to borax often suffer from chronic eczema; long-term exposure to borax dust may lead to inflammation of the mucous membranes of the upper airways and to conjunctivitis.34 The NIOSH REL and the ACGIH TLV for borax is 5 mg/m3 . OSHA does not have a PEL for borax. However, OSHA concluded that an 8-hour TWA of 10 mg/m3 (under the vacated 1989 PELs) was appropriate for the tetraborates and that this limit would substantially reduce the risks of eye, skin, and respiratory irritation caused by all forms of sodium tetraborate.

Summarized from NIOSH cellulose insulation evaluations (full text available here )

Attic Observations:

- The attic space was entered and visually inspected for conditions that may contribute to the noted concerns (insulation dust in the living space).

- Areas of potential air infiltration were observed and noted, including the sheet-rock chases around the skylights, perforations in the recessed lighting fixtures, and miscellaneous penetrations.

- White dust was observed on the sheet-rock ceiling near the kitchen skylight chase, and was patterned in a manner that was consistent with air-flow due to depressurization.

- No insulation was observed on the skylight chases.

- The exhaust fan and return ducting all appeared properly installed and adequately sealed.

- Evidence of stained framing around the rafters where safety-clips were installed was noted. This condition does not appear to be related to the indoor air quality concerns that were the cause for the inspection.

HVAC:

- The home is heated by a forced-air natural gas furnace and heat-pump located in the garage.

- The furnace is filtered by a high-quality filter box capable of housing a 4” pleated media filter.

- No obvious combustion-safety concerns were observed at the time of inspection.

- The fresh-air intake duct is not equipped with a mechanical damper or timer, and the manual damper was screwed in the open position at the time of inspection. This condition prevents adjustment as would be typical for this type of installation.

- Corrosion on the pipes for the hot water tank suggest periods of exhaust gas spillage at some point in the past, but CO levels were not measured above 0 ppm in the garage.

Final recommendations:

- The client may choose to have chemical analysis of the dust and insulation performed to guarantee that the crystalline materials observed are borates stemming immediately from the attic insulation, but the inspector is satisfied that sufficient data to support this hypothesis is present in this report.

- Detailed air-sealing should be performed on all accessible penetrations in the attic, including areas at the skylight chases and air-lock covers or trim rings for all recessed lighting fixtures.

- The home’s ventilation system should be rethought and the fresh-air intake system managed by a mechanical damper and timer, or deleted and bathroom exhaust fans controlled by timers. (calculations can be made at the client’s request based on data present in the ventilation section of this report).

- After air-sealing, the depressurization of the home must be mitigated, and verified to have been resolved without causing any possible combustion safety concerns, methods include:

- Installation of passive wall vents.

- Replace several windows with vented units.

- All settled dust should be removed from the home, although no formal protocols for borate dust contamination exist the following techniques would be consistent with mold spore mitigation*:

- Install large HEPA scrubbers while working to address dust that may be aerosolized during the cleaning.

- Perform a detailed HEPA vacuuming of all surfaces and exposed contents in the home

- Perform professional carpet cleaning and cleaning of any suspect soft-surfaces

- Perform a wet wipe down of any surfaces that still show evidence of visible dust (i.e. window sills, tops of cabinetry, tops of doors etc)*alternatively ,the client may choose a less costly approach to cleaning and simply perform a thorough “spring-cleaning”, dusting, and carpet cleaning. This may not be effective as the borate dust particles may be small enough pass through a regular vacuum filter and the dust may remain airborne during cleaning.

Comments are closed.