Carbon monoxide alarms are vital pieces of safety equipment used to protect workers and residents from poisonous carbon monoxide gas. But, did you know that hydrogen gas from charging batteries can set off the alarms as well. The post below is from a real case, and shows how hydrogen gas can trigger these alarms and potentially become an explosive hazard

Background information:

On Friday the client had installed 2 carbon monoxide alarms in the office portion of the facility. One carbon monoxide alarm was installed in the upper level on one on the lower level. During the weekend both alarms went off; yet no gas-fired furnaces, appliances, or forklifts were in operation. The client had then requested data-logging and investigation to determine the reason that the carbon monoxide alarms were activated. Once hydrogen gas concerns were noted, the meters were left at the facility to serve as safety alarms while the investigation was being performed and were removed completely the following week.

Summary:

Based on the testing performed and outlined below, it is the inspector’s opinion that most likely reason for the alarm activation of the carbon monoxide alarms is a buildup of hydrogen gas due to charging of large quantities of batteries and electric forklifts in an area that is insufficiently ventilated. Cross-sensitivity between carbon monoxide detectors and hydrogen gas is well documented and publicized. Additionally, high levels of hydrogen gas were measured at the charging stations, confirming that this gas is produced in measurable quantities when the chargers are in use.

Recommendations:

Based on the lower-explosive-limit readings (up to approximately 17% LEL) measured in the upper office space during the initial data-logging period, a combustion hazard is likely to be present when charging batteries or forklifts without sufficient ventilation. The charging should be ceased until appropriate ventilation can be achieved. Battery charging stations should be located in well-ventilated areas, as per the manufacturer’s recommendations. This may be achieved in a variety of ways including:

- Installation of large roof-mounted exhaust fans of sufficient size and operational duration.

- Installation of exhaust hoods of sufficient size above all battery charging areas

- Relocation of battery charging areas to outside of the warehouse space

The client should consult with the department of labor and industries and the local fire marshal to determine what types of on-site monitoring will be necessary for this facility. This may include:

- Commercial quality carbon monoxide alarms

- Explosive gas meters

- Additional fire-safety equipment, plans, or training

*This information has been provided for investigative purposes only, and should not be construed as formal plan for resolution of the issues that have been identified.

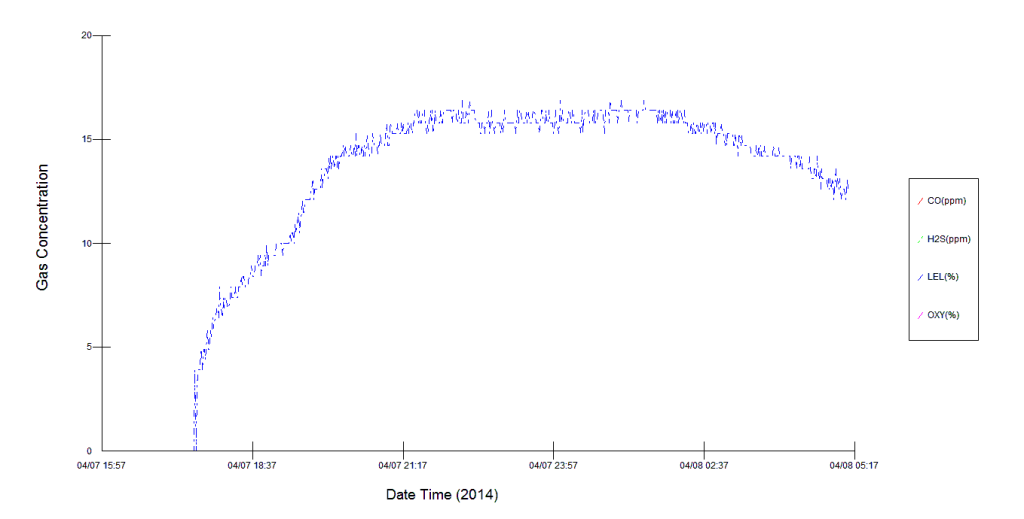

Data-logging graphs:

The chart below shows a slow elevation in LEL (lower explosive limit) readings from the evening of April 7th through the morning of April 8th. This unit was located in the upper level admin offices. No elevated carbon monoxide levels were seen during this monitoring period, and the LEL measured is assumed to be hydrogen gas generated by the battery charging stations and forklift charging stations

The graph below reflects moderately elevated levels of carbon monoxide throughout the weekend of 4-11-2014 thru 4-14-2014. Based on the additional information gathered during hydrogen gas testing and other periods of data-logging it is assumed that these levels are not actually carbon monoxide, but rather cross-sensitivity of hydrgen gas

Hydrogen gas testing:

To provide additional evidence that hydrogen gas is being generated in significant quantities by the battery charging areas and forklift charging stations a Dielectric MGD-2002 meter calibrated to H2 gas with a sensitivity of 25 ppm was used. The probe was moved above the batteries that were charging on pallets and immediately above the battery compartment in the Yale forklift. The following results were gathered:

Location | Time after start | Hydrogen Gas | LEL % |

Outdoors | ——————————– | 0 ppm | 0% |

2′ above batteries charging on pallet (bay doors open) | ——————————– | 275 ppm | 0% |

Far end of warehouse (furthest distance from charging batteries) | ——————————– | 25 ppm | 0% |

Yale Forklift Battery Compartment | 0 minutes | 100 ppm | 0% |

Yale Forklift Battery Compartment | 2 minutes | 275 ppm | 0% |

Yale Forklift Battery Compartment | 8 minutes | 750 ppm | 0% |

Yale Forklift Battery Compartment | 10 minutes | 1,000 ppm | 0% |

Yale Forklift Battery Compartment | 15 minutes | 1,175 ppm | 0% |

Yale Forklift Battery Compartment | 20 minutes | 1,575 ppm | 0% *50 ppm carbon monoxide measured at this time, suggesting cross-sensitivity between H2 and CO |

Final thoughts:

Safety equipment used in residential and commercial spaces is a vital and valuable tool to alert occupants of potentially hazardous conditions. If the alarms on these devices are being activated it may take a professional investigation to get to the root of the issue. As you can see above, what looked like a carbon monoxide concern actually turned out to be a potential explosive hazard. If you have any concerns about the health and safety of the air in your building, please call the experts at Hawk Environmental Services today for more information.

Comments are closed.